George Bazirake: Upscaling banana plantain for diaspora market

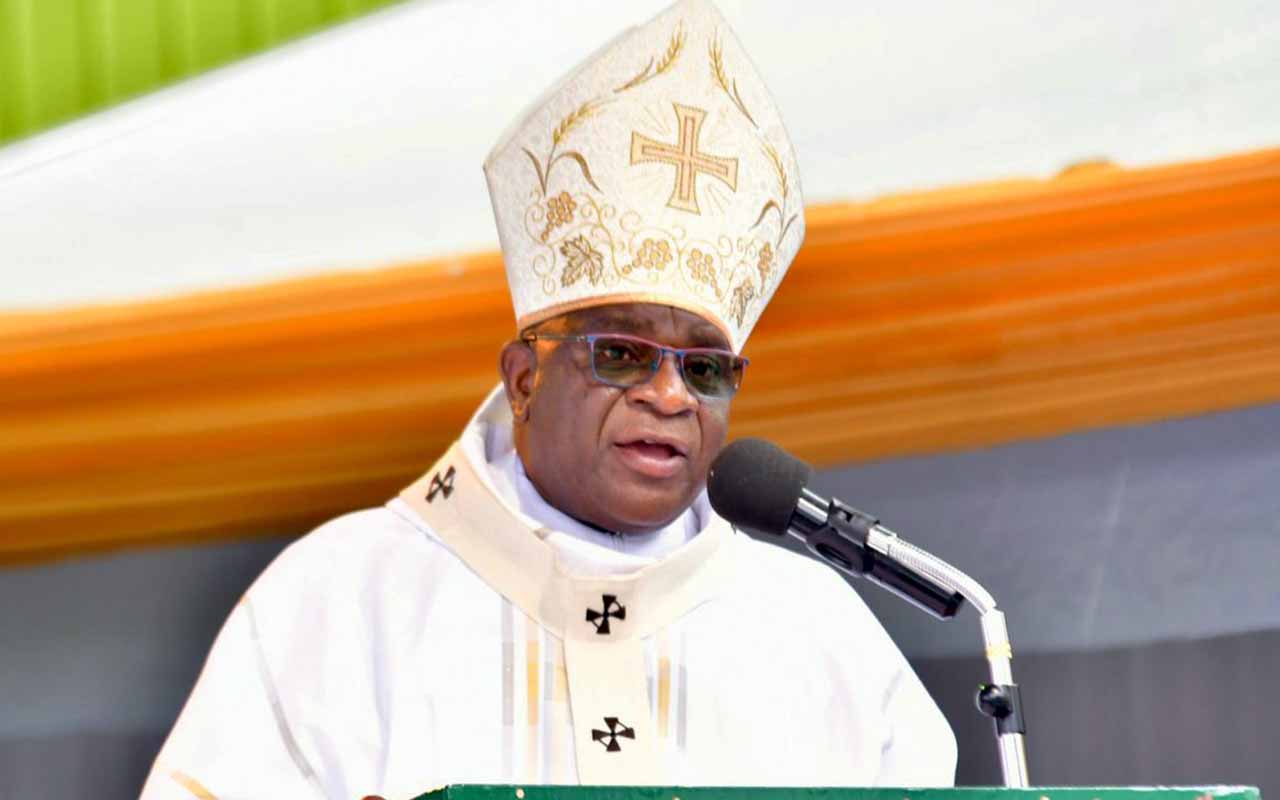

Mr Bazirake displays a table mat made out of banana fibre. Photo by Lominda Afedraru.

Instead of letting bananas ripen and go to waste, he peels them and packages them for export.

The peeled vacuum packed bananas (matooke) packaged in sterile sealed plastic to preserve them and increase their value are a special delicacy for East Africans living in the Diaspora.

Started in 2008 as a research project by Dr George Byaruhanga Bazirake as the lead researcher, proprietor and dean faculty of science at Kyambogo University, Afri Banana products Limited (ABP) adds value to banana plantain (matooke).

“I felt propelled to preserve and prolong the shelf life of the peeled matooke as food stuff consumed by most people in East Africa,” Mr Bazirake said.

Mr Bazirake, says his company is registered by guarantee and not-for-profit making or dividends with Kyambogo University as a lead institution.

Other items

Other items he produces out of banana fibre are; biodegradable bags that cost between Shs1, 000 and Shs1,800 depending on the size and quality, banana made textiles such as table cloth, ear rings, hair clips, and sandals.

The wrist rings cost Shs800, hair clips -Shs1,500, slippers -Shs2,200 and ear rings- Shs1,200.

“My colleagues and I also found the need to make use of the banana fibres by making simple products which can be used by our communities inform of crafts,” he said.

Dr Bazirake and his team established that over 520 tons of banana waste accumulating around Kampala originated from matooke peels which they are now using for making vinegar, biogas, enriched animal feeds, charcoal briquettes and organic manure which are at experimental level.

Dr Bazirake together with a team of scientists from Uganda Industrial Research Institute (UIRI), Kenya Agricultural Research Institute (KARI) and Must and Excel Hort Consult, formed a consortium to compete for funding where they won a $2 million grant to market the products.

The team embarked on producing different matooke varieties.

Using a jaw peeling machine, the matooke is peeled. Thereafter, sodium metabolic sulphite is applied onto it to keep it fresh. The matooke is then packed in vacuum sealed plastic packaging material and the labelled product is kept under chilled temperature in refrigerators.

Shelf life

The product can stay fresh for six months.“So far, we are packing the product in one-kiloggramme packages which we export to the United States of America and United Kingdom and we sell each kilogramme at $6.

The project has been patented and acquired reasonable capital to export to the two countries, and we are soon beginning to export to Dubai because we have already established a marketing strategy there,” he said.

This innovation, according to Dr Bazirake, has reduced the bulk of matooke by 40 per cent; thereby, enabling his team to transport it by air.

The marketing system operates in such a way that ABP Limitedd identifies companies interested in purchasing the product from Uganda, and transports it to the final destination for marketing.

The Business manager, Mr Joshua Ankunda explained that the company deals with three clients in the United States of America, one takes two tonnes of the product and the two take one tonne each on monthly basis.

In the United Kingdom, they have two clients whose order rates differ and sometimes Ugandan living there give direct orders for their consumption.

“We get Shs4 million from every tonne of matooke transported which is a low cost price because the profit margin is about eight per cent,” Mr Ankunda said.

The team started marketing their products in 2011 and Mr Ankunda is optimistic about rolling out the product on the Ugandan market.