Farmers earn double from molasses

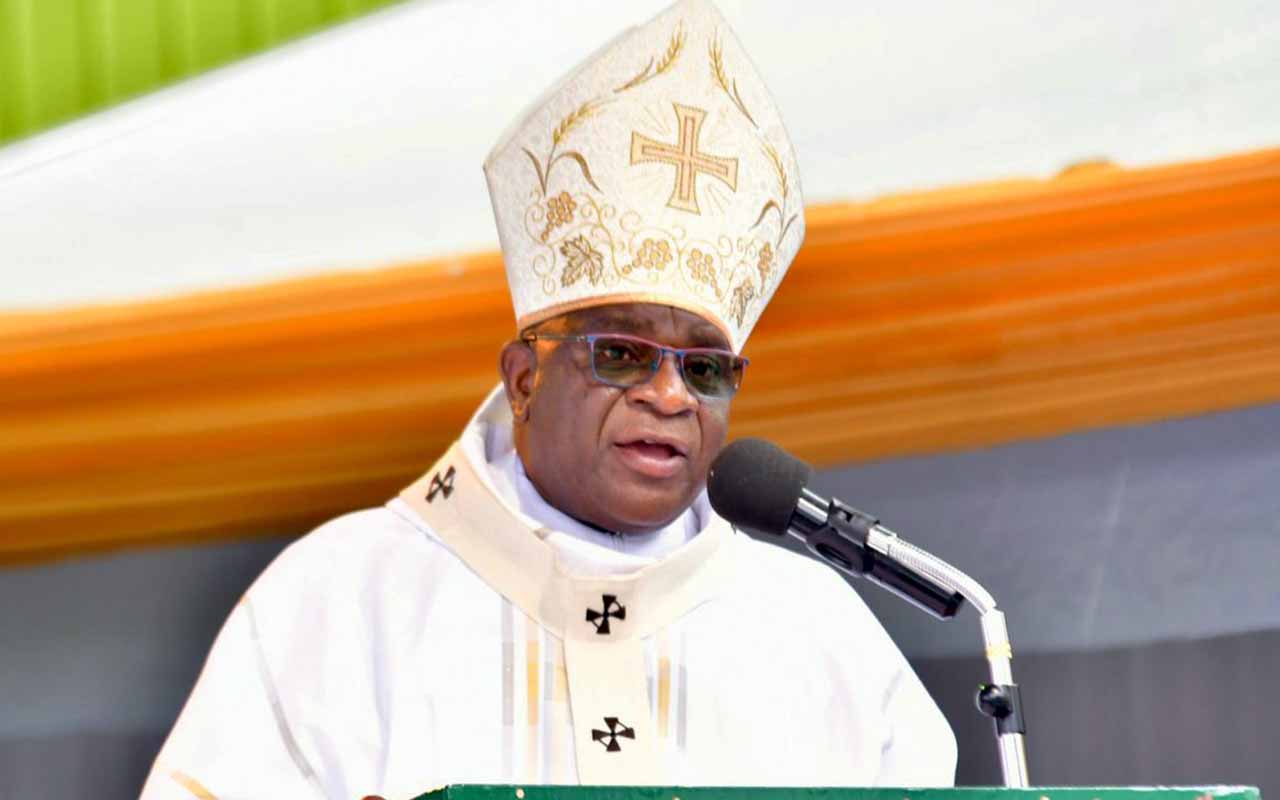

Joseph Nyombi (L) supervises the boiling of sugarcane juice at Aventino Nakaana’s farm. Photo by Michael J Ssali

What you need to know:

- Farmers are processing molasses from sugarcane. Their profits have more than doubled as they sell to distillation firms, writes Michael J Ssali.

- Peter Kagiri of Katikamu, Luweero District is another farmer making money from value addition. Kagiri grows the Saccharum Edule type of sugarcane. Until 2016, the 40 year-old farmer says he was earning Shs100,000 from 10 tonnes to middlemen.

Aventino Nakaana, of Manja Village, Kisekka Sub-county, in Lwengo District has been growing sugarcanes for the last 40 years for his daily income.

Before value addition, Aventino says he was earning Shs100,000 per tonne from sugarcanes. He would sell them to students and town dwellers.

“The money was too small yet I was putting in a lot,” says Aventino.

Turning point

A few months ago he was visited by two young men from Kidda in Masaka Municipality, Joseph Nyombi and Richard Bwanika, who introduced a new idea to him.

“They said they wanted to buy all the mature sugarcanes in the garden, regardless of their size. They had a machine that crashes the sugarcanes and extracts the juice which they would boil to make molasses right here in the garden,” says Aventino.

In February he came to an agreement with the young men who paid him Shs1.5m to cut down all the mature sugarcanes for making molasses.

They also agreed to return after about four months to engage in a similar activity and perhaps pay him the same amount of money or even more depending on the quality of the sugarcanes then. “Whenever I have done any harvesting or pruning, I have used the trash as mulch in the coffee and banana gardens,” Aventino explains.

“Now with the arrival of these young men and their juice extraction machine, I have more material for mulching because I retain all the leftovers here. When I sold the sugarcanes before the buyers took away everything.”

For Nyombi and Bwanika, squeezing juice from sugarcane and making molasses is increasingly becoming a daily occupation. They jointly own an improvised sugarcane crushing machine that was locally made in Masaka Town.

“We keep visiting sugarcane farmers in the region like Aventino and spend some days on their farms making molasses,” said Bwanika.

In some cases we buy sugarcanes from the farmer and in other cases the farmer pays us for making molasses out of his or her sugarcane.

He sells the molasses at about Shs2,500 per kilogramme.

He said they have visited sugarcane farmers at Kikungwe, Ssaza, Bisanje, Kirimya, Malembo, within Masaka District and several other farmers in Kyotera and Rakai districts.

Their machine is not constructed to use an engine but rather to be operated manually by two people, one on either side, pushing a long pole fixed to it.

Peter Kagiri of Katikamu, Luweero District is another farmer making money from value addition. Kagiri grows the Saccharum Edule type of sugarcane. Until 2016, the 40 year-old farmer says he was earning Shs100,000 from 10 tonnes to middlemen.

Kagiri took a different path after visiting Uganda Industrial Research Institute (UIRI) in 2017.

“I realised I would make more money if I processed my sugarcane into molasses. I got the training in January before investing in a processing unit. Today I am a happy farmer earning double what I used to earn,” he says adding “I do not sell my sugarcane to middlemen anymore, but process it into different products such as molasses, which fetch more money.” From one tonne of sugarcanes, Kagiri extracts more than 100 kilogrammes of molasses. Unlike Aventino, Kagiri sells each kilogramme of molasses at Shs3,000 to distilling industries earning Shs300,000 per tonne.

The process

Molasses is a by-product from the processing of sugar cane. It is a thick, gooey, sticky substance that can be used for sweetening because of its high concentration of sulfur dioxide derived from the extraction of sugar.

The actual act of extracting molasses from sugar cane involves three separate stages to its production. You can stop at any one of these stages and have molasses of some consistency.

The progression of these steps simply changes the taste and thickness of the molasses by extracting a certain amount of the sugar.

Steps

Step 1

Strip the sugar cane of all of its leaves with a carving knife. This must be done for the extraction of any molasses so that everything that is not necessary to the actual production of the molasses is out of the way.

Step 2

Crush the sugar cane to extract a thick, melon-colored juice. Do this in a standard sized mortar and pestle. Using a larger mortar and pestle will allow you to grind more of the sugar cane at a time, but will also create more of a mess. Once all of the sugarcane has been crushed to release a good portion of juice, you can remove the outer part of the sugarcane from the mortar and pestle leaving only the melon-colored juice in the bowel. Pour this juice into a pot and heat it on a stove or fire until it reaches a rolling boil. The boiling of the juice promotes a crystallization of the sugar, allowing it to form the most base stage of molasses, also known as First Molasses.

Step 3

Cool the molasses off in a fridge for three to 12 hours, or until it cools to about 50 degrees Fahrenheit. Then, pour the molasses back into a boiling pot and bring it to a boil again. This will promote the additional evaporation of the sugar, giving the molasses a stronger, bitterer taste. It will retain much of its sweetness, though it will become much thicker with the re-boiling.

Step 4

Repeat this step again, bringing the cooled molasses back to a boil to create the final possible stage of molasses. This molasses will be very thick and black-colored. This molasses is known as Black-strap. It has very little sweetness, instead containing iron, potassium, calcium, sodium and magnesium, making it highly medicinal.