How farmers process fuel from seeds

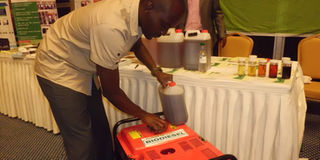

A farmer holds a five-litre jerrycan containing biodisel. Below, a researcher at NaRL displays a paper bag . Photo by Lominda Afedraru

What you need to know:

- Naro Scientists process biodiesel from recycled vegetable oil, making innovation from farm products. The fuel is mainly used by farmers to run tractors and generators, writes Lominda Afedraru.

- The team has already acquired a pump ready for use at the Institute and at the moment their clients are mainly farmers using farm equipment.

It is important to note that farmers growing crops that produce oil mainly referred to as vegetable cooking oil are contributing a great deal in terms of provision of pure cooking oil.

The crops include soybean, simsim, groundnuts, and sunflower among others.

Usually people, who use the vegetable oil for cooking on large scale, end up recycling the same which is hazardous to human health.

As such scientists at the National Crop Resources Research Institute and their colleagues at the National Agricultural Research Laboratories (NaRL) at Kawanda are carrying out innovations by processing the used vegetable oil for creating biodiesel, glycerin liquid cosmetic oil and environmentally friendly carriage bags.

Innovation

Dr Ephraim Nuwamanya in charge of the Biochemistry Lab at NaCRRI explaining how used vegetable oil is being processed at the institute to make the above products during a case study meeting of innovations conducted by Naro scientists in Kampala notes that a number of people are recycling vegetable oil which is already oxidised for cooking.

This he says is dangerous to human health and may end up causing cancer the reason Naro scientists picked up interest to collect such used oil to be processed into biodiesel.

The scientists are teaming up with hotels who are heavily engaged in recycling used vegetables oils for cooking. They are already partnering with Hotel Africana management who are supplying them with used oil product. They intend to collaborate with major hotels in most towns in Uganda in order to get the required quantity of raw material

Paper bags

Ronald Atwaza, a research assistant at NaRL explained that the glycerin purified from used oil and the catalyst is used for processing environment friendly plastic bags which are degradable.

The team processes starch from cassava peels and the outer part of pilled cassava tuber.

The glycerin is mixed with the processed starch powder and a bit of water mixture. It is then put in an oven for three hours for a paper to be produced.

This can be cut in different shapes to be assembled into a paper bay.

The essence is to produce these bags for supply in super markets and other commercial enterprises to avoid use of plastic bags which are dangerous to the soil.

At the moment the production rate is low and suppliers have to make an order for processing to be implemented.

Naro’s take

The Director Naro Dr Ambrose Agona noted that it is time for agricultural scientists to carry out research and innovate products which can be commercialised by farmers.

Processing

Enoch Wembabazi a biochemist research assistant at NaCRRI taking stakeholders through the processing of biodiesel explains that at the laboratory, scientists generate a catalyst from egg cells which is grinded into powder and this is mixed with ethanol extracted from cassava.

It is mixed with the used vegetable oil and the output is processed biodiesel ready to power engines of tractors and generators which use diesel.

A measurement of 100 litres of used vegetable oil requires one kilogramme of processed catalyst and 15 litres of ethanol. This mixture will produce 92 per cent of biodiesel.

This mixture can be further purified to get glycerin liquid cosmetic oil ready for use.

“Once the mixture is done, it takes an hour to turn into biodiesel,” says Wembabazi who is also a farmer of vegetable oil crops. Wembabazi and other farmers have started processing biodiesel from the oils they produce.

Dr Nuwamanya explains that since tractors require pure diesel for initial powering, 40 per cent of original diesel is added to the processed biodiesel.

This means in 10 litres of biodiesel 400 ml of pure diesel has to be added for the tractor to power.

Since a generator has light engine, there is no need to add diesel to the processed biodiesel meaning it can be used directly for powering a generator. In old engine tractors manufactured in 1990’s pure biodiesel is used for powering.

The team has already acquired a pump ready for use at the Institute and at the moment their clients are mainly farmers using farm equipment.

They produce the biodiesel upon a placed order.

Pure biodiesel is sold at Shs1, 800 per litre. The plan is to open outlets in regions to avoid clients travel all the way from upcountry to purchase biodiesel at Namulonge.