How a family has turned cocoa beans into chocolate

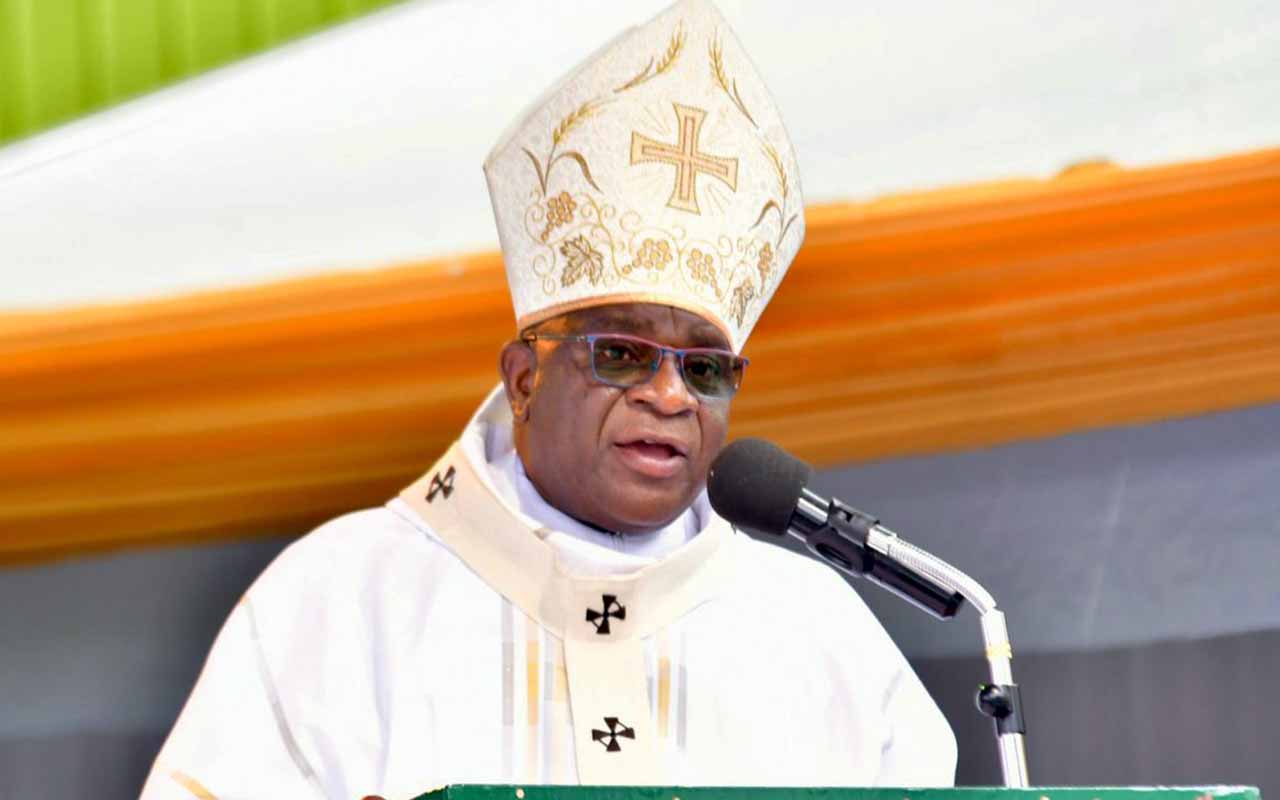

Jovan Ssekindi harvests cocoa beans from the 600-acre farm in Mukono. The cocoa beans are dried before they are taken to a processing plant where they are turned into chocolate. Right: Stephen Sembuya nibbles at a chocolate bar made from the processing firm. PHOTO BY DOMINIC BUKENYA

What you need to know:

Value addition. After the death of the late Yafesi Magulu in the 80s, the founder of Magulu Cocoa Farm in Mukono, his two grandsons found it worthwhile to build on his legacy. One of them manages the farm while the other uses the same raw material—cocoa—to process chocolate bars, cocoa powder and cocoa butter.

It is probably the country’s biggest cocoa farm standing on more than 600 acres of land.

Located about 64 kilometres, off Mukono Katosi road in Lugonjo village-Nkonkonjeru Sub-county in Buikwe District, the farm is well-known by residents in this area where cocoa once prospered as a cash crop.

Magulu Cocoa Farm was established by the late Yafesi Magulu, in the 1940s. Initially, it started off as a banana plantation until the 1950s when cocoa was introduced into the country as one of the cash crops.

Edward Mubiru, the manager of the farm and grandson of late Magulu shares: “Our grandfather was inspired to start planting cocoa within banana plantations when the crop was introduced into the country.”

He approached the forestry department and got a lease to expand into the forest reserve. He was advised to plant trees which would increase the forest cover and at the same time act as shades for cocoa since the commodity thrives under the shade.

“Our grandfather loved cocoa so much and wanted it to succeed in Uganda. So, he travelled to Ghana and Ivory Coast, the leading producers in the World, among others, to seek for knowledge on how to grow cocoa and this helped him grow his farm,” Mr Mubiru narrates.

Magulu passes on

However, in the late 80s, due to old age that comes with illnesses, Magulu became weak and was forced out of the business, transferring responsibility to his sons to manage the farm.

His son Paul Wasswa who owned Kiwa Industries took over management but later passed on.

Then his brother Christopher Ssembuya of Sembule Steel Mills took over management of the business in the early 90s when Magulu succumbed to illnesses and eventually passed on.

However, due to the multiple challenges Ssembuya was going through with his company Ssembule, the farm was neglected for some years because no one was willing or had time to take control.

“The farm was dilapidated for some years until the family gave me the responsibility to be the caretaker then,” Mubiru adds.

After takeover

In 2011, when Mubiru took over the management of the farm, his major task was to rehabilitate the crop.

He had to deal with residents who had turned the farm into a source of timber through cutting trees which provided shelter to the cocoa and this saw many cocoa plants destroyed.

Currently, Mubiru employes 50 people to prune, weed and harvest the crop.

His biggest challenge is the little manpower for the farm to operate at full capacity.

“Our aim is to increase on the number of employees to reach at least 300. That’s when we shall be able to operate at full capacity,” Mubiru added.

In the last two years, they have rehabilitated 120 acres and his target is to see that the rest of the farm is up and running in the next five years.

He is optimistic that by that time, they will be able to harvest at least 80 to 100 tonnes of cocoa beans from the current 20 tonnes.

Peak seasons

July is the first peak harvesting season while November to December is the second. Every fortnight, farmers harvest cocoa pods.

A cocoa tree reaches peak production in 10 years and will continue producing pods for an additional 12 to13 years. Shade-grown cocoa trees can produce pods for 75 to 100 years or more.

Currently, they harvest about a tonne and half of cocoa beans monthly. This is translated into about 20 tonnes annually. Yet if it was operating at full capacity, these figures would more than double.

They sell their cocoa beans to Esco (U) Ltd and Olam (U) Ltd.

Yovan Ssekindi, the farm caretaker for more than 30 years, says: “When we harvest the ripe cocoa pods, we remove them and ferment them for seven days in a box. After two days, we change for proper fermentation to take place.”

After the seven days, they put the beans in the sun to dry and this takes four days. Then they sort them and pack them in sacks ready to be picked by the exporters.

Sourcing for exports

From the 20 tonnes produced of cocoa beans annually, each kilogramme is sold at the maximum of Shs7,000 depending on the global market price and this is translated into Shs140 million annual earnings for the last two-years since they resumed operations.

He says the profit from the farm is spent on maintenance and paying workers.

“Our target is to have cleared the entire farm in the next five years and it will be producing at full capacity. This means the yields will have doubled or tripled the production,” Mubiru promises.

Every month, they need about Shs5 million to manage the farm but currently they spend about Shs2.5 million in operational costs.

Chocolate division

Stephen Ssembuya, also a grandson of late Magulu, is handling the processing wing of the cocoa into finished chocolate, cocoa powder and cocoa butter.

Ssembuya, under the flagship of Pink Foods Industries situated in Gayaza, is looking at processing chocolate and biscuits.

Talking about his source of inspiration, Ssembuya said: “Given the background that my grandfather and my father have all been involved in cocoa growing, I saw a gap that all the cocoa Uganda produces is taken out of the country with little or no value addition.”

That is why he researched on how he could make chocolate, cocoa powder and cocoa butter.

“We are currently producing samples of chocolate and sending them out for experts’ advice on its taste and also we are in the final stages of patenting our machinery so that full production starts in the next two months,” Ssembuya shares.

Currently, they have invested Shs500 million into the machinery alone and are looking at creating jobs for 20 people at the processing plant.

Chocolate process

Ssembuya says the process starts from the farm, where cocoa pods are harvested. They then remove the beans from the pods, ferment, and dry them before they are taken to the factory to remove the husks.

Then the beans are put into the roaster, and the cracker machine crushes the beans into nibs which are put into the grinder to make a paste. Then a Champion Juicer and Millender machine puts the refined chocolate into the molds.

Types of chocolate

They will be making several types of chocolates. First, they will be specialising in dark chocolates, flavoured chocolate which is mixed with peanuts, plantain and simsim and later they shall introduce white chocolates from the cocoa butter.

When their chocolate hits the market, it will be traded under the brand named ‘Kiss Chocolate.’

In the next month, sampling of cocoa butter will be done. This could be used in making cocoa butter, white chocolate and cocoa powder that will be used as a raw material for confectionaries also.

The machinery

They are using both artisan and commercial machinery imported from the US and China. They have also fabricated some locally.

When production starts, the machinery will be producing about 100 kilogrammes of chocolate every day.

They have already started getting orders from confectionery companies, which use chocolate in their production and part of it will be used in making biscuits.

Challenges

Maintaining the cocoa farm and establishing the chocolate processing plant have constrained the family financially.

“Many people don’t believe this can be done locally,” Ssembuya explains.

Tracing genuine herbicides has also been difficult because most of those on the market are substandard yet expensive.

“We hope to rehabilitate the entire farm so that it gets back to its glory,” Mubiru promises.

Advice

He says someone interested in growing cocoa should have enough land and produce it massively to plough back investments.

They should also research and consult agronomy experts on how it is planted.

Uganda’s cocoa exports stop at the fermentation stage and are transformed into cocoa powder and the chocolate is then brought back as expensive imports.

In 2013, about $52 million (Shs130 billion) worth of cocoa was exported in its raw form. Yet if this had been processed into chocolate, drinking chocolate powder or cocoa butter, the country’s earnings would be more.

A kilogramme of cocoa beans costs Shs7,000 at the farm-gate price, but when it is processed into chocolate, the same kilogramme could earn between Shs400,000 and Shs500,000.

“As a family, we don’t want to stop at producing the beans. We are adding value to the beans to make chocolate,” Mubiru shares.

He adds that this will not only create more jobs for Ugandans but also bring in revenue in addition to branding the country as one of the chocolate producers; thus saving money spent on expensive imports.

Future plans

They have approached the Ministry of Agriculture and the experts in the cocoa sub-sector to help them improve this farm with research.

Mubiru says when full rehabilitation is done, Magulu Cocoa farm will be used as a model which can be visited by schools and institutions of higher learning involved in agriculture.