Understanding your car’s axles

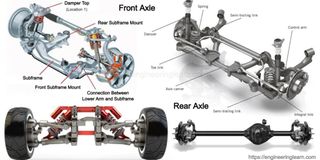

Diagram showing three types of axles. PHOTOs/www.engineeringlearn.com

What you need to know:

Several parts work together to keep your car moving and one of these is the car axle

While you might not be a mechanic, understanding how your car’s parts work helps to ensure that you know when your car is not functioning as it should. Several parts work together to keep your car moving and one of these is the car axle. You need axles for steering, driving, and braking, hence they play a part in nearly every element of vehicle operation.

Robin Byaruhanga, of Deutsche Auto UG in Bukoto, Kampala, says an axle is a rod or shaft that rotates the wheels and supports the weight of a vehicle. He adds that axles are essential components of any vehicle and come in three main types; front, rear, and stub.

“All vehicles have axles. The difference is in their size and significance, which are based on the size of the vehicle as well as the load the car is meant to carry,” he says, adding that the axle is at the heart of car movement because if a car does not have them, then it would not be able to transfer kinetic energy (energy of motion) from the drivetrain to the wheels. You can categorise axles based on their position.

Front axle

It is found at the front of the vehicle and controls the front wheels. Wilson Kasekende, a mechanic at Kizza Motor Garage in Kampala says this axle works to assist in steering the vehicle and process any shock from uneven roads.

There are two types of the front axle:

• Live front axle, which rotates and as it does, delivers driving power from the gearbox to the front wheels.

• Dead front axle: Unlike the live front axle, the dead front axle, also known as the lazy axle does not rotate the wheels. Therefore, this axle is on the drive train and is freely rotating, used to mount bearings, wheels sometimes even gears.

Rear axles

These are located in between the differential and work to move power (kinetic energy) from the differential to the back wheels during acceleration. The differential (also known as a diff) is responsible for distributing power from the drive train to the left and right wheels.

“Therefore, it allows for the difference in speed between the inside and outside wheel when turning,” Kasekende says.

He further explains that the rear axle is made up of two halves; the differential connects the two parts and each part is called a half shaft. “This axle may actually be said to rotate simultaneously with the vehicle’s wheels,” he adds. There are three types of the rear axle:

• Full floating rear axle: Just as the name suggests, Byaruhanga says this rear axle type floats in place and maintains its position, by the help of two bearings (tapered ball bearings).

“These are designed to transfer driving torque (a measure of the force that can cause an object to rotate about an axis) only, and usually work best for heavy duty vehicles such as haul trucks. These axles also work in medium sized trucks, giving them the capability to tow heavy loads. Additionally, vehicles with four-wheel drive may also use them,” Byaruhanga explains.

• Semi floating rear axle: This connects the wheel to the flange on the outer side of the axle shaft, holding it securely. Byaruhanga explains that the axle works with two bearings where one supports the axle shaft while the other is placed inside the axle casing.

“Unlike the full floating and the three-quarter rear axles, the semi-floating axle must be larger to ably produce the same torque,” he says. This rear axle type is used for sports utility vehicles (SUVs), and mid-size trucks, such as light duty pick-ups.

• Three quarter floating rear axle: Although it is more complex than the semi-floating axle and also more reliable, it is not as good as the full floating rear axle. Therefore, Byaruhanga says, it is a compromise between the two rear axle types.

“It helps in ensuring that wheel alignment is well maintained while also handling side thrust and driving torque,” he says.

Stub axle

There are four types of the stub axles to choose from:

• Elliot: This uses the a kingpin, a yoke, and a cotter to connect it to the front axle.

• Reverse Elliot: It works with the reverse arrangement of the standard Elliot stub axle.

• Lamoine: This stub axle type has an L-shaped spindle, which it uses instead of the yoke-type hinge.

• Reverse Lamoine: It works with the reverse arrangement a standard Lamoine stub axle.

So, how many axles does each car have? Kasekende says for every pair of tyres, there should be an axle.

“For most passenger or ordinary cars, there are two axles; one at the front and another at the back. On the other hand, larger vehicles, seeing that they have more wheels, might need more axles,” he adds.

Maintenance

Since axles are metals, they wear out over time due to rust and overweight. One can also wear down the axle sooner if they roughly handle the vehicle.

“Driving on rough terrain or uneven surfaces, more so doing so in a rough manner can cause excessive wear to the axle,” Byaruhanga says.

Spotting malfunction

According to Wilson Kasekende, a mechanic at Kizza Motor Garage in Kampala, when the axle is malfunctioning, there are some tell-tale signs including:

• An unusual clunking sound as you engage the gear.

• Vibrations in the vehicle, usually as you turn or brake.

• Excessive movement or extra effort needed to make a turn.

• Faulty axles will also affect your car’s wheel alignment.