First oil: Kingfisher rig to be installed by December

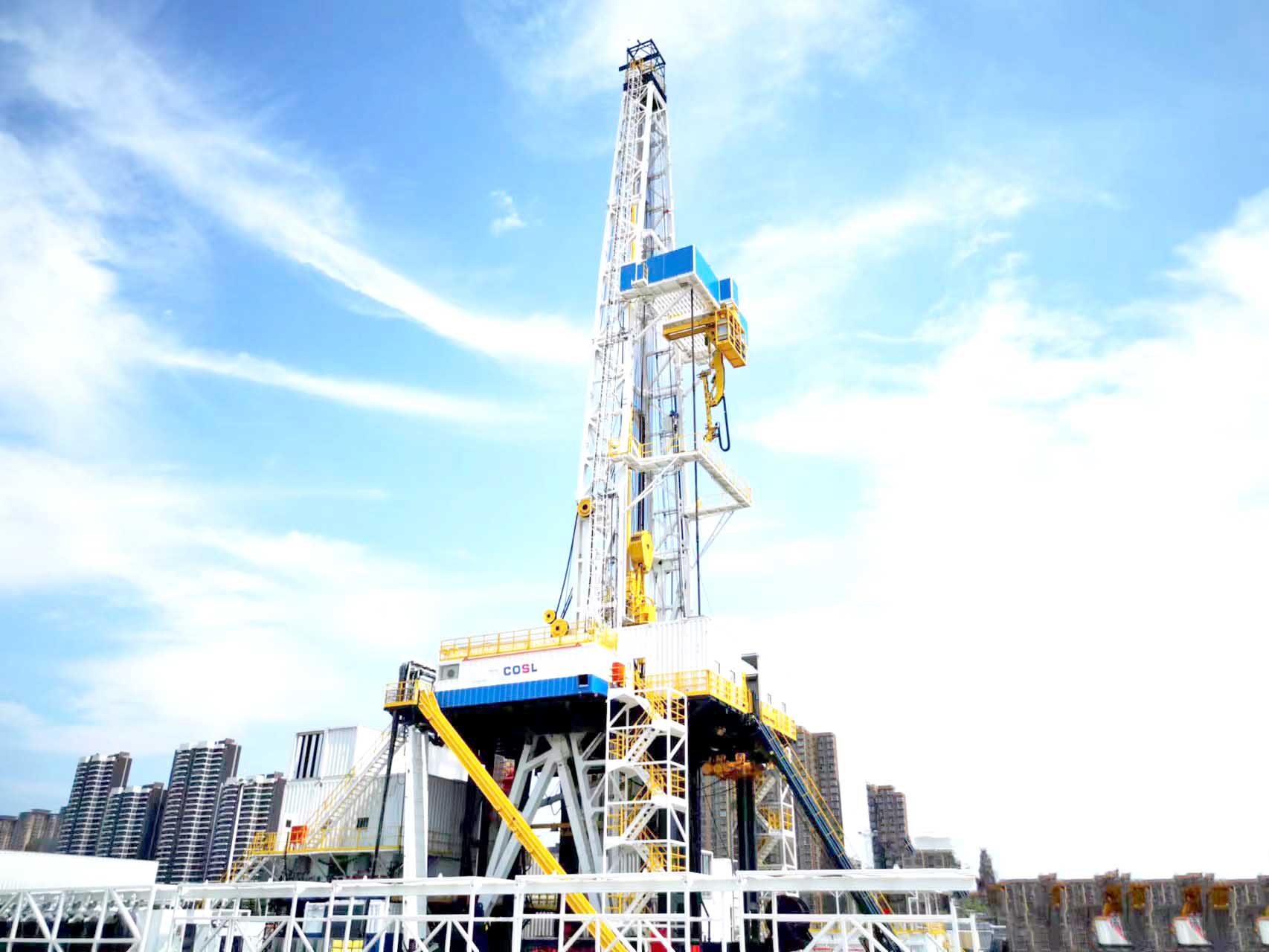

The rig for Kingfisher Development Area at its plant site in China. PHOTO | CNOOC

The first consignment of parts for the oil drilling rig dubbed LR8001 on Monday arrived at the Kingfisher oil field in Kikuube District at the parallels of Lake Albert, adding impetus to ongoing plans to start commercial oil production in the last quarter of 2025.

The Kingfisher oil field is part of the Kingfisher Field Development Area that straddles Kikuube and Hoima districts in mid-western Uganda, operated by Cnooc Uganda Ltd.

The remaining rig parts, Cnooc says, will be hauled daily for the next three weeks by 18 container trucks from Mombasa port to Malaba en route to mid-western Uganda.

The complete set of the rig equipment is expected to be assembled and installed by December 15 to allow test drilling.

According to Cnooc, the automated silent rig is equipped with industry-leading technologies, including well site de-noising control, zero discharge system and pipe column automation system.

“The whole set of equipment supports the integrated operation of various wellbore and well types, and during the operation effectively protects the regional ecological environment,” Cnooc said in an earlier statement to celebrate the first consignment of rig parts departing north China’s Yantai port along the Bohai Sea. The rig was constructed by China Oilfield Services Ltd.

The company described the customised mega oil equipment as “a landmark achievement of Chinese oil equipment to transition to environmental friendliness, low carbon and intellectualisation” and a key project under Chinese President Xi Jinping’s Belt and Road Initiative, launched in 2013 to enhance connectivity through some 65 countries and gathering 62 percent of the world population from mainland China through Asia, Europe and Africa.

The oil rig will be used in horizontal directional drilling, where, as opposed to moving the rig to each well pad, it is stationed at one well pad and one or two or more oil wells plugged onto a single well pad using conductor pipes. Then through careful planning, well trained navigators and guiding software, a driller guides a drill bit through conductor pipes across the oil wells over a long distance.

A well pad is a site of facilities and other infrastructure for oil and gas drilling. The planned rig will enable drilling of 31 wells at the Kingfisher field.

Clean bill of health

On Monday, the Cnooc Uganda Ltd president, Mr Chen Zhuobiao, met the Petroleum Authority of Uganda (PAU) executive director, Mr Ernest Rubondo, and appraised him of the developments.

“This rig has been shipped right in time for the planned drilling that begins in December. Commendable!” Mr Rubondo said, according to a statement from PAU.

The Kingfisher, formerly known as Exploration Area (EA) 3A, is where drilling led to announcement of discovery of commercial oil volumes in 2006.

Following completion of the farm down in 2011 and the company commencing operations in Uganda in late February 2012, Cnooc Uganda Ltd was tapped as operator of the EA3. At the time, only the Kingfisher field had a production licence, which had been conditionally granted to Tullow during course of the farm down.

The company, however, had to wait for another eight years until February 1, 2022, when along with the joint venture partners — Total Energies EP, Uganda National Oil Company, and Tanzania Petroleum Development Corporation — announced Final Investment Decision (FID) for the Uganda oil project to move to the next development phase. The stock tank of oil in place in the KFDA is estimated at an average 800 million barrels, of which, 25 percent will be developed in phase one — producing 40,000 barrels of oil daily during peak production.

TOTAL ENERGIES’ RIG

Meanwhile, Total Energies EP’s first drilling rig to be employed at the company’s Tilenga oil project that straddles Nwoya and Buliisa district also underwent and passed endurance tests recently.

The Tilenga project will employ five rigs; three north of the River Nile inside the Murchison Falls National Park, and two across the Nile in Buliisa. There are nine well pads inside the park on which the three rigs will be looped and drilled to extract oil, and transported by a network of pipelines— flour lines—that will be laid [and buried] crossing the River Nile en route to the Central Processing Facility (CPF) in Buliisa.

Final retouching of the Total Energies EP’s rigs by Zhongyuan Petroleum Exploration Bureau (or ZPEB) Uganda Ltd is underway in Guanghan city, China. The first rig is expected in the country later in December.