Prime

Uganda discovers new aflatoxin control means

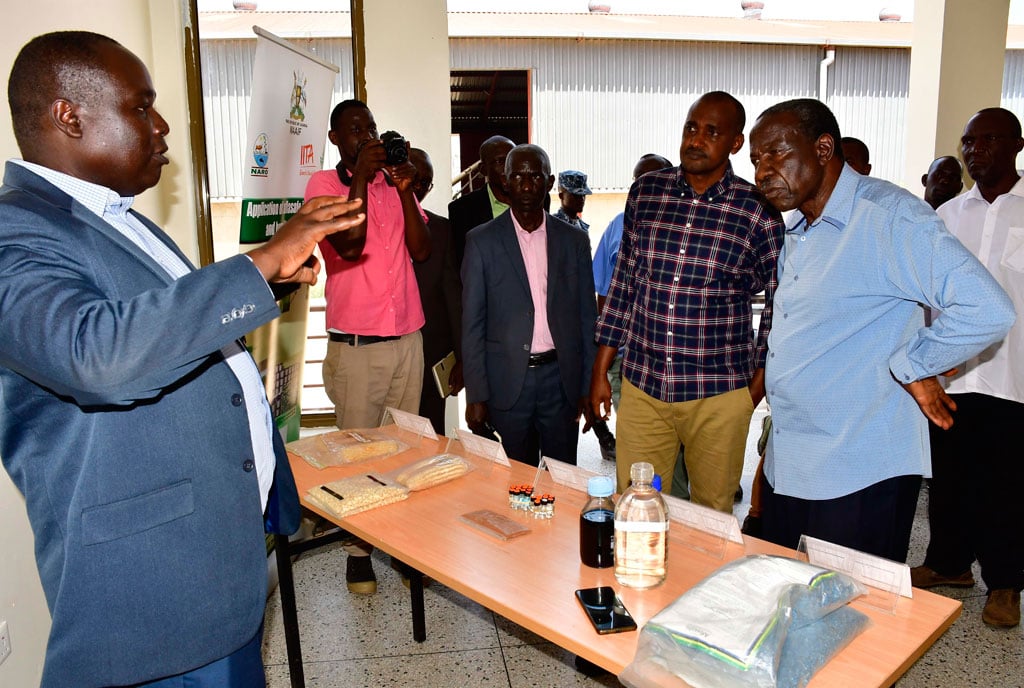

Dr Godfrey Asea (left), the director for research at NaCRRI, explains to Finance Minister Matia Kasaija (right) and his Agriculture counterpart Frank Tumwebaze (2nd right) the technology they have developed to fight aflatoxin-causing fungus on February 14, 2023. PHOTO/COURTESY

What you need to know:

- Naro wants government to provide Shs300b annually to bankroll transformation of innovations to reality and address problems encountered by farmers.

Ugandan scientists at the National Agricultural Research Organisation (Naro) have announced a major breakthrough in developing a product, named Aflasafe, which they said during trials reduced pre-harvest aflatoxin contamination by 80 percent upwards.

News of the discovery comes as a relief in the wake of findings by National Crops Resources Research Institute (NaCRRI) researchers that maize, sorghum and groundnuts in all areas growing the grains in Uganda are contaminated with aflatoxin above World Health Organisation’s maximum threshold.

In a statement issued yesterday, Naro Director General Ambrose Agona noted that “the government of Uganda, through Naro, has been and is funding research efforts towards aflatoxin control and management, and these efforts have led to a solution called Aflasafe”.

“Naro has prioritised research on food and [animal and poultry] feed safety and has built capacity on aflatoxin research and testing for routine analysis of samples,” he noted.

The Aflasafe is still a laboratory product and unavailable on the market for farmers and grain dealers, pending validation of research on its effectiveness, registration and patenting.

While hosting line Agriculture minister Frank Tumwebaze and his Finance counterpart, Mr Matia Kasaija, on February 14, Naro officials asked the government to provide Shs300b annually to bankroll transformation of innovations to reality and address problems encountered by farmers.

Dr Yona Baguma, the Naro deputy director general for Research Coordination, said they need Shs60b to enable commercial production of Tick vaccines for which a shell facility has already been constructed.

Mr Tumwebaze during the February 14 visit said that if the government capitalised Naro, it could produce and help farmers buy affordable and quality animal feeds.

“If Naro is fully-funded, they are able to commercialise their products and in five to ten years, [the] government may not be required to put its money here, he said, adding, “If the initial investment is substantial, everything here can make money. They can even generate their own electricity and sell to the national grid. They need to scale, brand and market if we are to support it initially.”

ALSO READ: Aflatoxins hurt farmers’ earnings

In a rejoinder, Mr Kasaija said “personally, I would want to wean Naro off government funding, I want them to become a big industry so that they can compete with anyone in the market”.

“But right now they need some more money,” he said, “Keep going, we are proud of you the scientists. Do not go and sleep. Continue studying until death asks you to go away. Technology is coming, discoveries are coming.”

Established in 2005, the organisation is the government’s spearhead on agricultural research, including crops, livestock, fisheries, forestry, agro-machinery, natural resources and socio-economics, according to information on its website.

The ministers visited Naro institutes to acclimatize themselves with their operations and assess their needs alongside evaluating firsthand the progress of the Tick vaccine factory ahead of President Museveni’s expected visits to the facilities.

In yesterday’s press statement, Dr Agona noted that cultural practices, biological control, host resistance, monitoring and crop destruction, grain drying, sorting, storage, post-harvest processing, and dietary interventions are recommended methods to reduce crop aflatoxin content and subsequent human and animal aflatoxin exposure.

Regarding animal and poultry feed safety, he announced that they had developed and patented a “Naro aflatoxin binder”, which comprises natural aluminosilicate clays obtained from the Albertine Graben Region.

“Once incorporated into animal feeds contaminated with aflatoxin, the binder sequesters the toxins from the feed and binds with them to form an insoluble complex which is then passed out of the animal’s body as part of the fecal material,” he noted.